When different

reels, e.g. foil reels, paper reels, or cylinders, are to be positioned in

packing, printing or production machines, the space is often limited around or

under the machine. The reels are often placed inside the machine, where the

manoeuvrability is limited. Positioning of the reels is difficult and hard to

the operator. Many customers have asked us to find a solution for

this application situation, and we have thus developed a Reel Lifter with

compact overall measurements and high manoeuvrability.

Our Reel Lifter

makes it much safer and ergonomically correct to position reels in complicated

places.

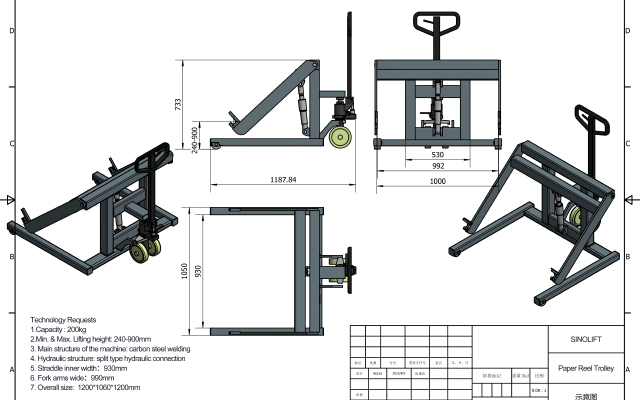

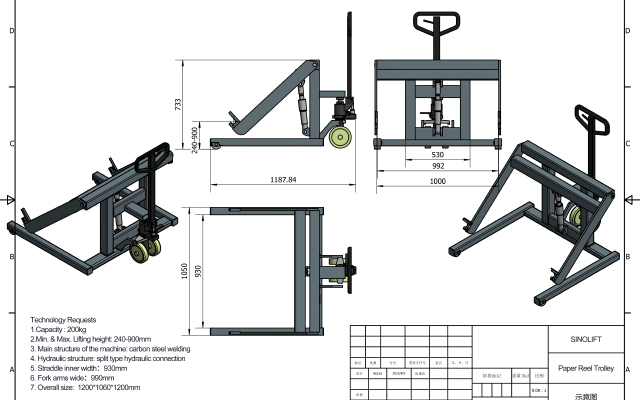

Technology Requests

1. Capacity: 200kg

2. Min. & Max.

Lifting height: 240-900mm

3. Main structure

of the machine: carbon steel welding

4. Hydraulic

structure: split type hydraulic connection

5. Straddle inner

width: 930mm

6. Fork arms wide: 990mm

7. Overall size: 1200*1060*1200mm

With this little helper, you can place different reels - e.g.

foil reels, paper reels, or cylinders - in packing machines, or unwinding and

production machines. The Reel Lifter is a perfect choice, when space is limited

around or under the machine, and when the reels are placed inside the machine,

where it is difficult to access.

In addition, the Reel Lifter is the perfect assist to our Reel

Rotator.

The Reel Lifter is compact and very manoeuvrable, and it can

position the reel in the correct place in the machine. It is the perfect

partner for the SINOLIFT Reel Rotator, which can take a reel from e.g. a

pallet, rotate it and place it onto the Reel Lifter. The Reel Lifter can also

be used together with a reel turning forklift attachment.

With the Reel Lifter you can safely and smoothly transport the

turned reels from the warehouse to the production area without damaging the

paper.

Picture: Packing customer's customized reel lifter

If you also have the same requirement, you can contact our email: sales@sinolift.com

|

Chinese

Chinese USA

USA English

English Russia

Russia